.png&w=3840&q=100)

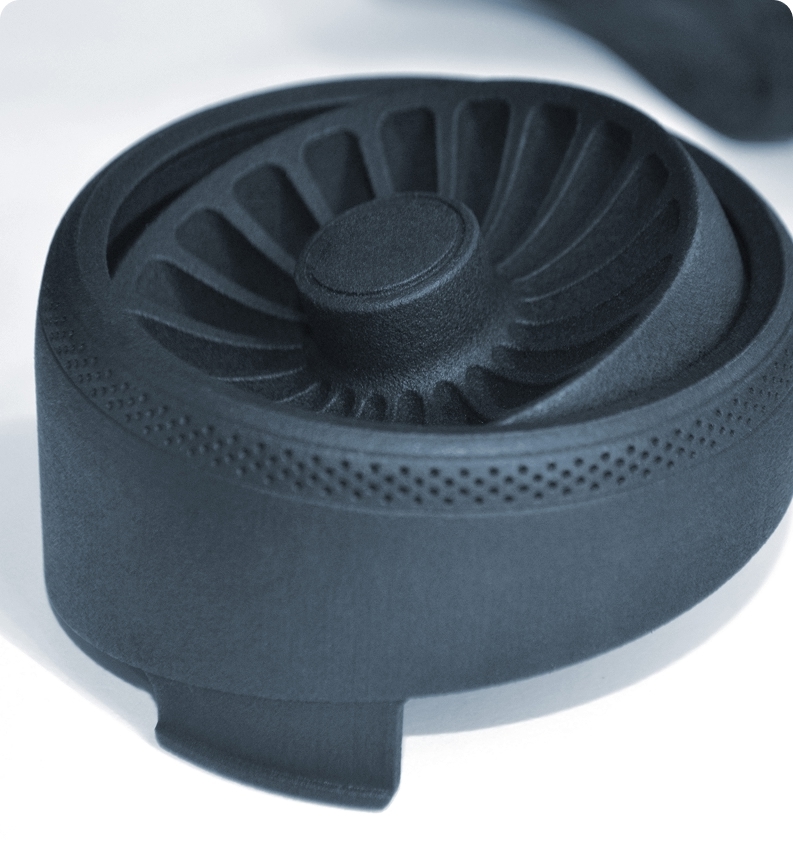

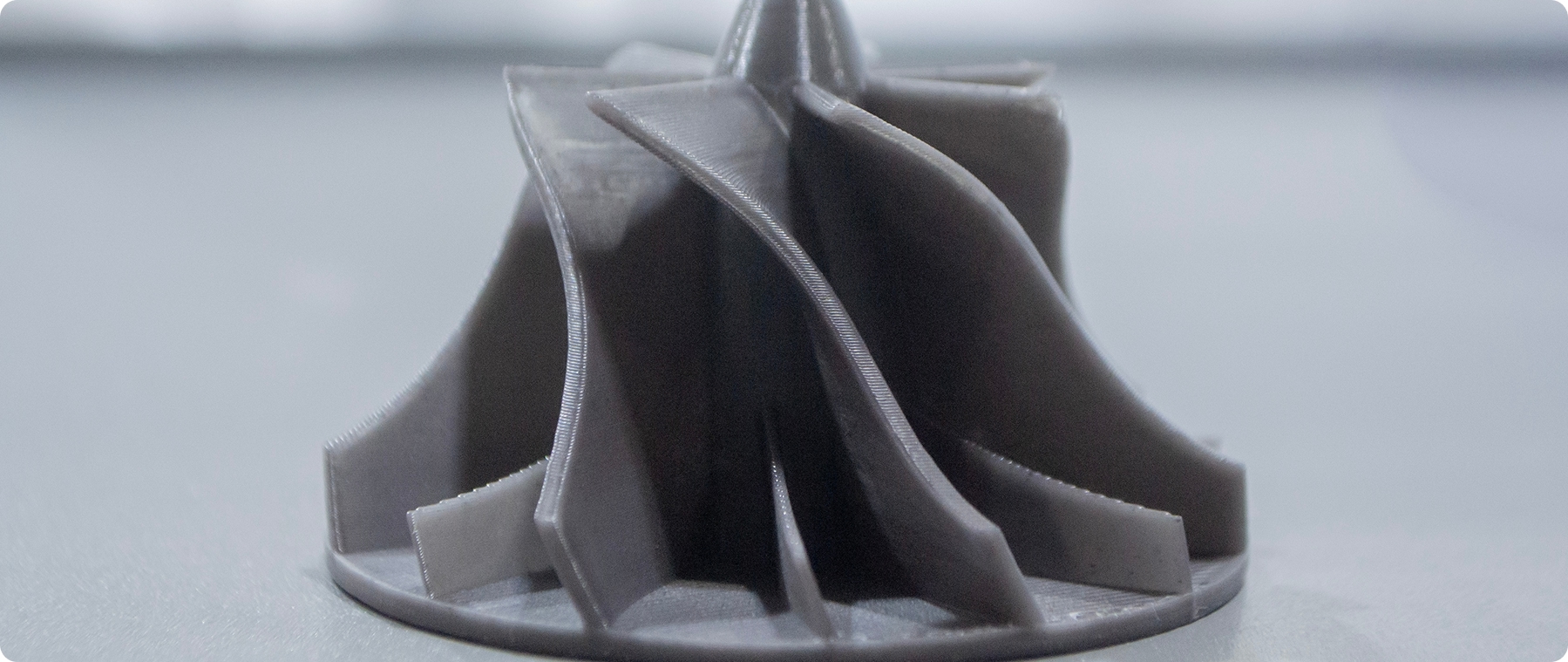

Contract manufacturing and industrial 3D printing

Produce faster. Save smarter. Deliver on time.

Produce faster. Save smarter. Deliver on time.

Long-term frame agreements

Ongoing cooperation based on a frame agreement guarantees price predictability, priority service, quick access to production, and streamlined purchasing processes.

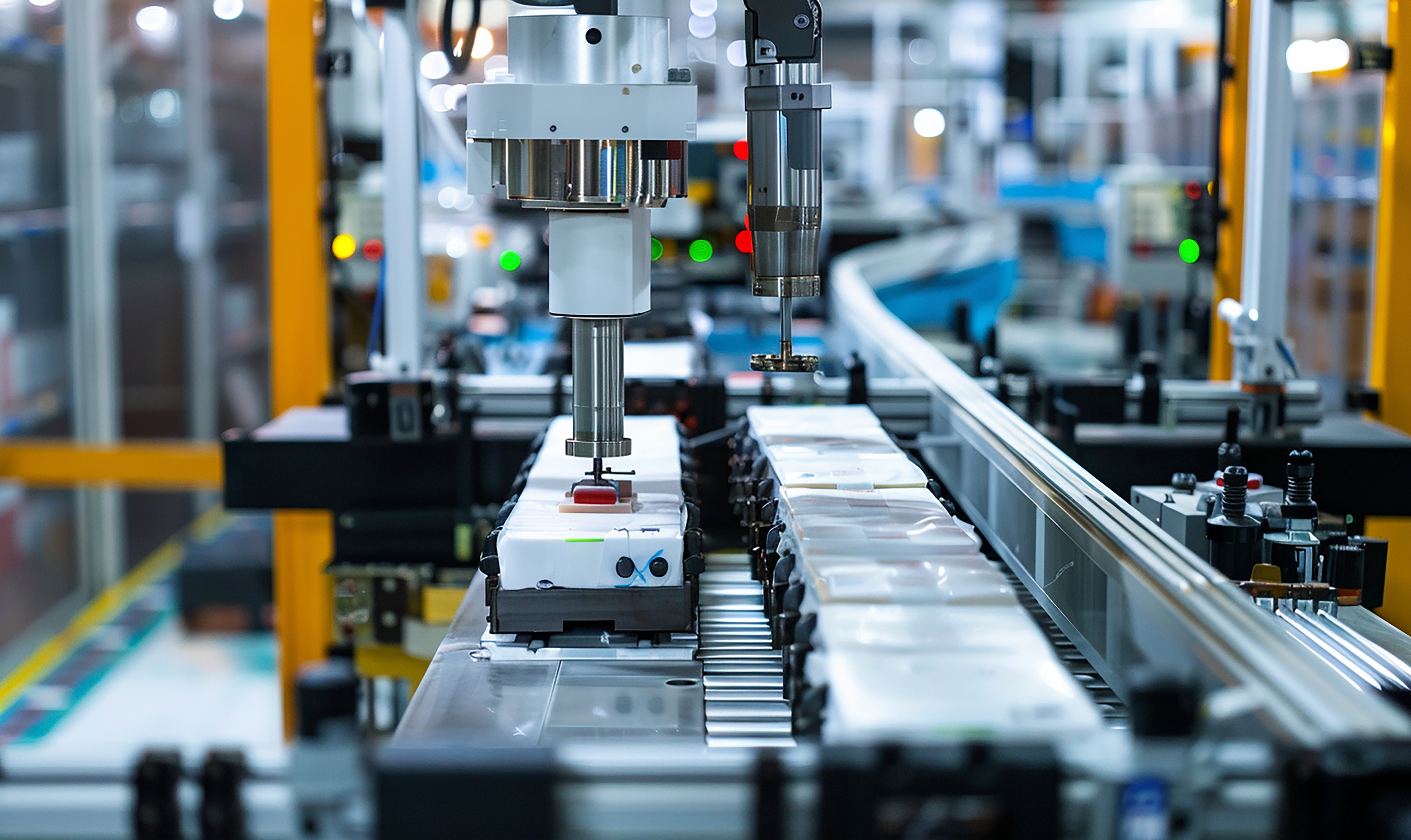

Cyclical production series service

We execute production series in set cycles — weekly, monthly, or on demand. We ensure timeliness, repeatability, and volume flexibility.

Customer inventory management

We maintain buffer stock levels of parts. Consignment stock, Kanban, or JIT – we adjust the delivery model to the customer's production rhythm.

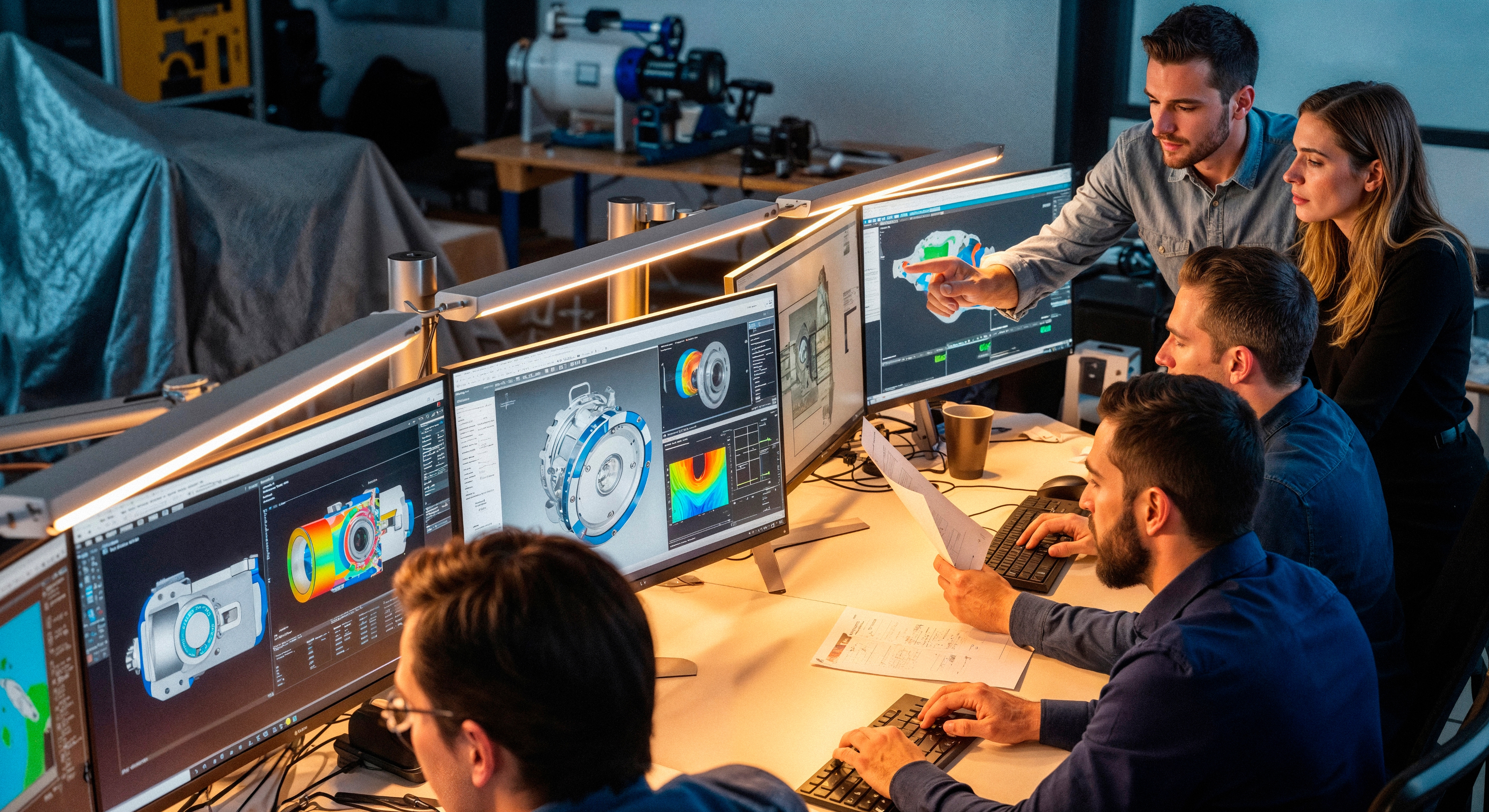

Contract manufacturing - process

Customer onboarding

We start contract manufacturing cooperation by thoroughly understanding the customer's needs and technically validating the project. Our proven onboarding process is as follows:

Delivery deadlines

Thanks to the high performance of our industrial 3D printers, we can quickly scale production.

We adapt to your production rhythm. We jointly set delivery schedules – these can be regular batches, e.g., weekly or monthly, or flexible series on demand. In the just-in-time model, we produce and ship exactly as many components as you currently need, minimizing frozen capital in inventory.

.png&w=3840&q=100)

Cost optimization

The usual break-even point for 3D printing compared to injection molding starts at several hundred pieces — depending on geometry complexity and dimensions.

Moreover, in additive manufacturing, you don’t have to freeze capital in tooling, which significantly reduces investment expenses.

Step 01

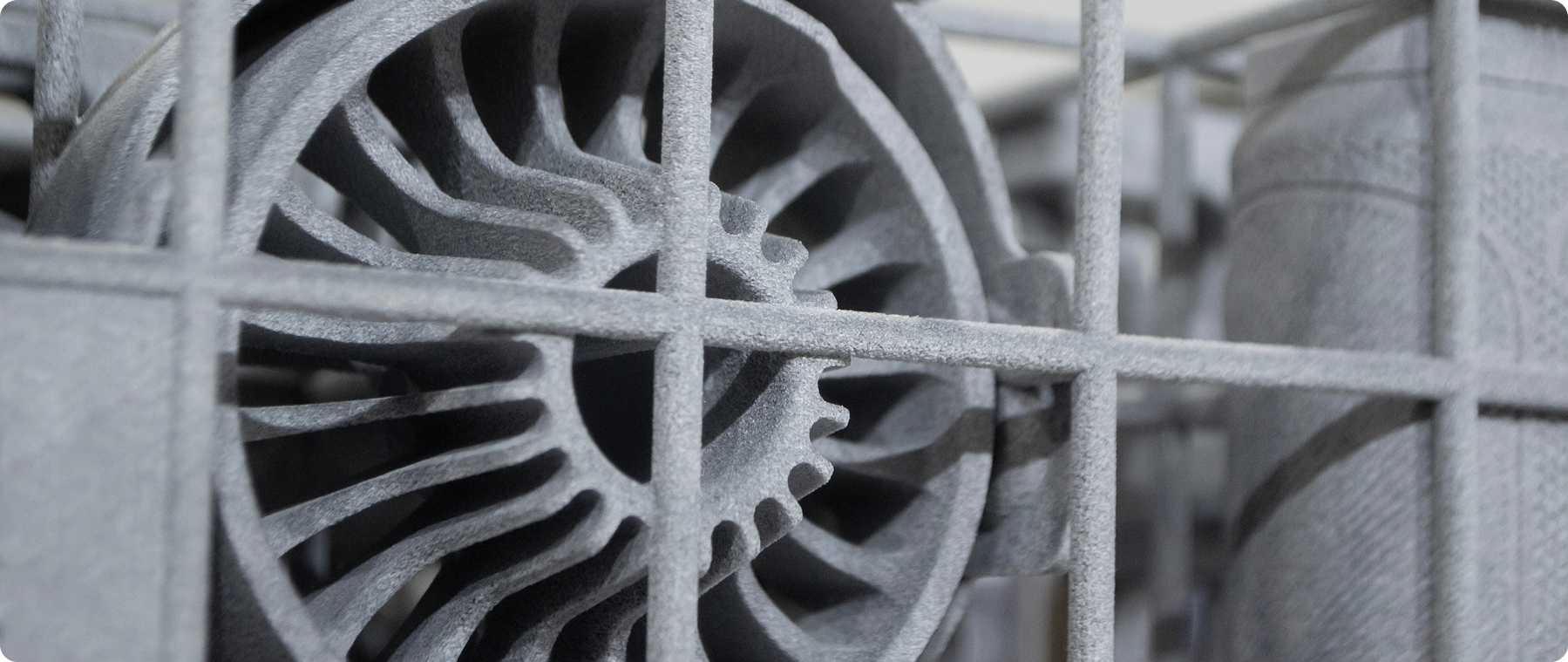

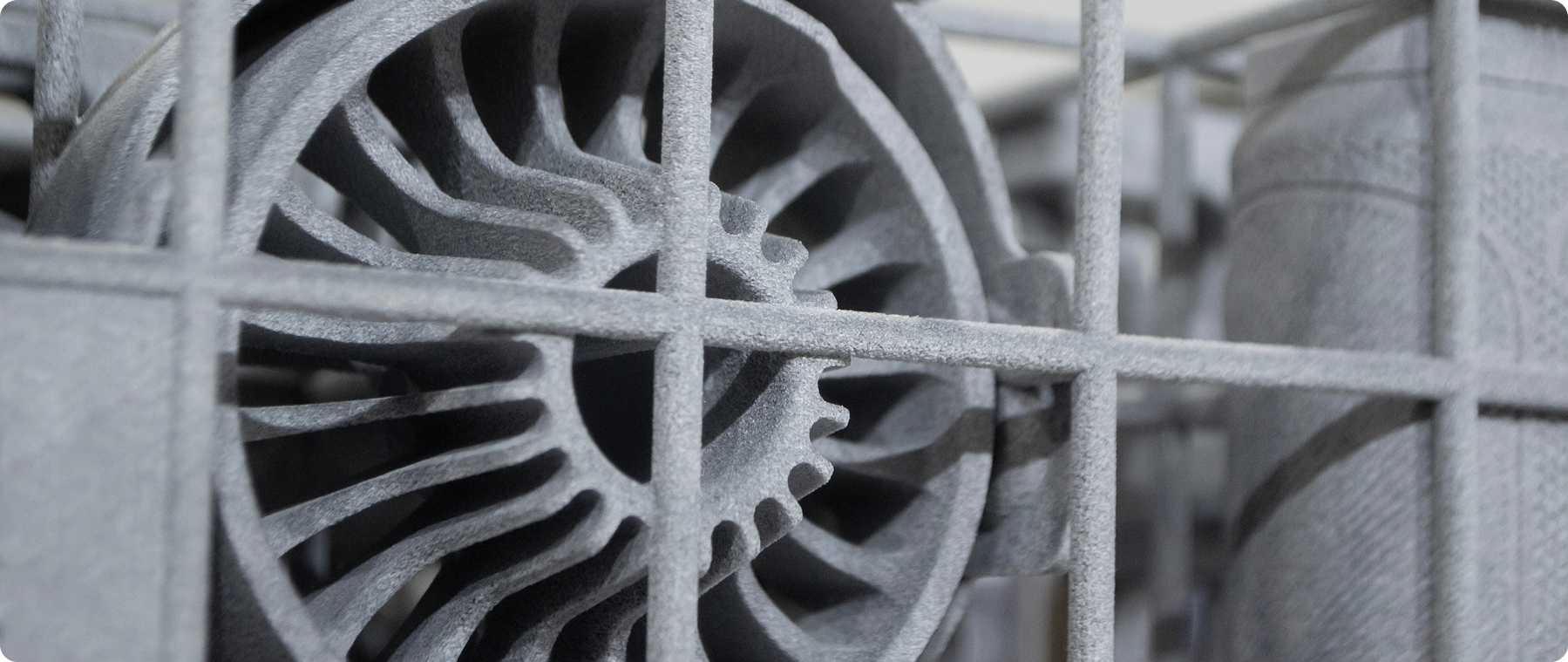

Repeatable quality and process stability

HP Multi Jet Fusion technology provides high dimensional accuracy and consistent mechanical properties. Each batch meets the same standards, ensuring reliability and full repeatability in mass production.

Step 02

Lower unit cost at volumes

Thanks to optimized print chamber loading, lack of mold costs, and process scalability, the unit cost significantly decreases with growing orders. Production becomes profitable even with medium series.

Step 03

CAPEX reduction and simpler supply chain

No investments in tools and machines mean lower initial costs. We produce locally, on demand, eliminating overproduction and reducing the need to store parts on the customer side.

Step 04

Complete quality documentation and traceability

Each batch is covered by quality control with FAI reports, inspection protocols, and process history. This ensures compliance with standards and full traceability of every piece.

SLA and quality guarantees of deliveries

Each agreement includes an SLA defining key production and service parameters – ensuring safety, predictability, and full responsibility.

The SLA specifies the maximum lead time for deliveries, consignment stock level, target quality indicators (ppm), and detailed complaint procedures.

We provide replacement of defective parts or batch correction. Cooperation includes KPI monitoring and quarterly performance reports.

Mass personalization and marking integration

We offer serial personalization of elements without affecting unit cost – each component can receive its own identification marking.

We implement serial numbering, QR codes, ID, or RFID tags integrated with the customer's warehouse system. Markings can be added during printing or applied in post-production, facilitating tracking, servicing, and logistics of each part.

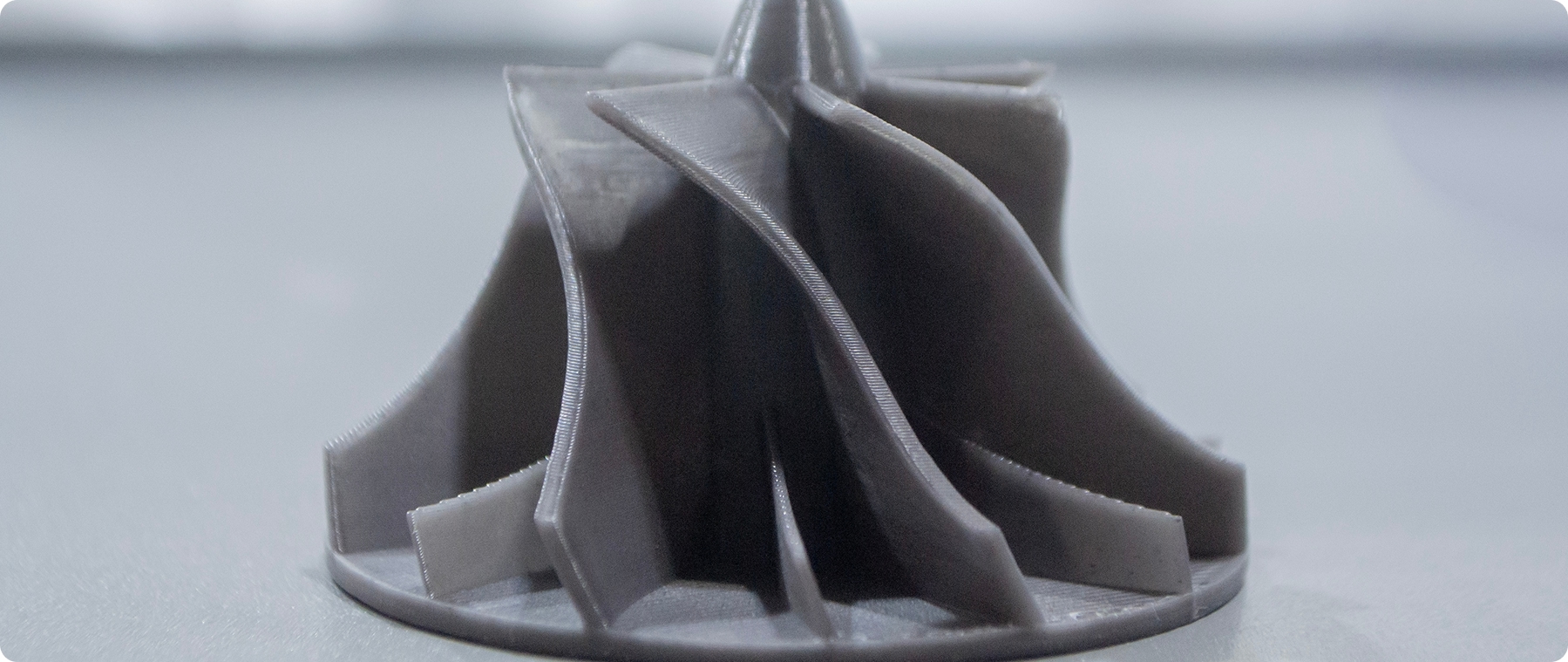

Types of surface finishes

MJF 3D printing at COSMOLD is a solution for companies that value flexibility, short lead times, and high quality. We support both startups and large industrial plants.

.jpg&w=3840&q=100)

Uncleaned sample

Raw surface without powder removal after printing. Rough, porous, and matte – ideal for comparing finishing effects in subsequent post-production stages.

.jpg&w=3840&q=100)

Cleaned sample

Basic cleaning from powder residue. Retains the natural material color and slightly rough texture. It's the starting point for further finishing stages.

.jpg&w=3840&q=100)

PolyShot Surfacing

Mechanical surface smoothing in the Powershot X system. Provides an even, satin matte and improves part aesthetics without affecting dimensions or tolerance.

.jpg&w=3840&q=100)

PolyShot + DeepDye

Combination of cleaning and coloring in DM60 technology. Parts gain an intense, deep color and a smooth, aesthetic surface with high durability.

.jpg&w=3840&q=100)

VaporFuse Surfacing

Advanced chemical smoothing in the Powerfuse S system. The resulting surface is sealed, glossy, and injection-molding like, providing protection against moisture and dirt.

.jpg&w=3840&q=100)

VaporFuse + DeepDye

Smoothing and coloring in one process. Elements achieve the highest class of aesthetics and durability – smooth, color-saturated, and ready for direct final use.

Assembly of subassemblies and completion of finished components

Besides printing and finishing, we offer assembly, functional testing, and packaging according to customer specifications.

We handle assembling elements into complete subassemblies – from press-fitting bushings, mechanical assembly, to electronics integration.

Finished sets undergo functional testing, are labeled, and packaged individually or collectively – ready for deployment on the production line.

Who is our service for?

MJF 3D printing at COSMOLD is a solution for companies that value flexibility, short lead times, and high quality. We support both startups and large industrial plants.

Machines and Equipment

Manufacturers

We execute regular component deliveries tailored to our customers' production schedules. With the just-in-time model, you eliminate excess inventory and free up funds from frozen capital.

Small companies

Startups

We help young companies launch production quickly – from initial prototypes to finished enclosures and functional elements. We share knowledge and experience, supporting the part design and optimization process.

Large production

Factories

We supply spare parts for production lines according to an established schedule, ensuring operational continuity and security of maintenance departments. Our contract manufacturing minimizes downtime risk and shortens response time.

Welcome to the Customer Zone

In the customer zone, you can quickly go from idea to realization. Got an STL file? Upload it and get a quote.

Medicine

Defense

Aviation and drones

Industry and manufacturing

Consumer goods

Architecture

Automotive

Electronics

Tooling

Robotics

FAQ

Popular questions

Our specialists answer the most frequently asked questions about HP Multi Jet Fusion (MJF) – the fastest growing additive manufacturing technology in the world.

Industry articles